Do You Need Food & Beverage

Gas Testing Services?

Gases have many uses in food and beverage manufacturing, including applications like carbonation of soft drinks, headspace blanketing, package filling, and cryogenic freezing of prepared foods. Through partnerships with regulatory and advisory groups like the Food and Drug Administration (FDA), Food Chemicals Codex (FCC), Compressed Gas Association (CGA), and the International Society of Beverage Technologists (ISBT), Atlantic Analytical Laboratory has developed numerous analytical methods that are now considered the benchmark for quality testing of food and beverage gases.

Visit our contact page or give us a call today to get started!

Beverage Grade

Carbon Dioxide

Carbon dioxide (CO2) is used to add effervescence (bubbles) to many different types of beverages during the manufacturing process. CO2 is commercially produced from a wide range of feed gas sources, including ethanol fermentation, refinery gas production, natural gas wells, coal gasification, cogeneration, and ammonia production, to name a few. Each CO2 feed gas source and associated purification system involves a unique set of analytical challenges that must be met to ensure final product CO2 quality.

Atlantic Analytical Laboratory has been an active member of the International Society of Beverage Technologists (ISBT) for almost 20 years; many of the analytical methods included in their guideline publications were initially developed at AAL. The published ISBT guideline for beverage grade carbon dioxide quality is considered to be the primary reference for CO2 analysis worldwide.

The beverage grade carbon dioxide analysis performed at Atlantic Analytical Laboratory is a comprehensive set of tests designed to detect and quantify the critical contaminants associated with carbon dioxide from all major feed gas sources. The analytical reports generated are tailored to match the current ISBT Carbon Dioxide Quality Guidelines exactly, so carbon dioxide suppliers can rest assured their product meets their end customer’s needs.

Beverage Grade

Nitrogen

Nitrogen (N2) is used for many different food and beverage applications, in both its cryogenic liquid and gas phases. Because nitrogen is distilled from the atmosphere around us, the potential impurity list is not nearly as complicated as the list for carbon dioxide (which is typically a by-product of other chemical processes or separated from natural gas sources). Once again, Atlantic Analytical Laboratory has worked closely with the International Society of Beverage Technologists (ISBT) to help develop the current Nitrogen Quality Guidelines. And if there are any other chemical impurities of concern that are specific to your source or your end user’s requirements, we can create a customized report format that will meet your needs.

Diverse Experience & Knowledge

Where We Are Today?

At Atlantic Analytical, we strive to give each customer the personalized attention they deserve, including direct access to our technical specialists for advice or to answer any questions. “Priority Rush” service can be selected whenever immediate results are necessary.

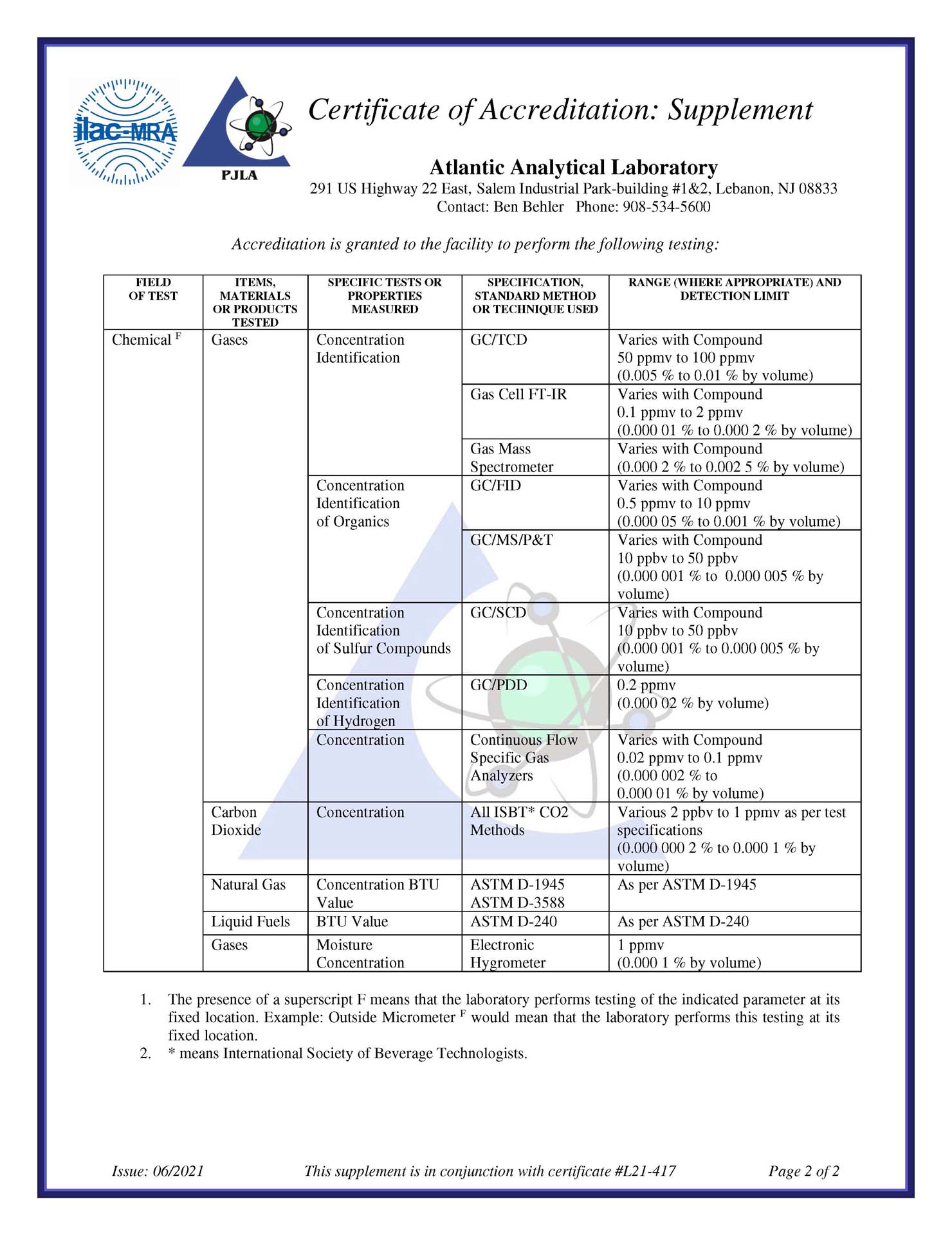

Our knowledge and experiences in gases and volatiles testing are diverse, yet highly specialized, with expertise in Gas Chromatography (GC), Mass Spectrometry (MS), Gas Mass Spectrometry (Gas-MS) and Fourier Transform Infra Red (FTIR) methodology for high purity gas analysis from the major gas chemicals and pharmaceutical producers; cryogenic air separation and impurity determination for Liquid Nitrogen (LIN), Liquid Oxygen (LOX), Liquid Argon (LAR); pharmaceutical applications such as USP, EP grade gases such as Nitrogen (by a comparable yet superior Mass Spec method), Oxygen, Carbon Dioxide and Medicinal Air; headspace analysis and custom methods; natural and fuel gases; manufactured synthetic gases; liquefied gases; Helium, Hydrogen and HyCO; beverage grade Carbon Dioxide; Air Analysis and Compressed Breathing Air for SCBA and SCUBA applications.

We comply with FDA, ISO/IEC 17025:2017, CGA, Mil. Spec, USP/NF, EP, ISBT, NFPA 99, and NFPA 1404 criteria, however our services go one step further. We also offer both on-site sampling & testing programs. Clients that benefit from these services include: pharmaceuticals, cogeneration power plants, manufacturing facilities, clinics, hospitals, companies concerned about indoor air quality or industrial hygiene, and landfill operators responsible for emission compliance. We are ISO Accredited, FDA Inspected “without a 483 being issued.” We offer a comprehensive package of analytical gas, volatiles and non-volatile impurities testing services to support your product development and marketed product activities.

The Gold Standard For Gas Analysis

Sample Submissions

The most critical step in any analytical program is initial sample collection – great care must be taken to ensure the sample collected is truly representative of the source. AAL has a large selection of sampling cylinders and other sampling equipment available for all types of gas and liquefied gas sampling. If you are uncomfortable collecting samples or just want to make sure everything goes smoothly, we can send one of our experienced personnel directly to your facility to collect samples on site for you. We look forward to working with you soon!