Do You Need Natural & Fuel

Gas Testing Services?

Natural gas and fuel gas analysis can be used to ensure fuel quality, evaluate commercial suppliers, determine turbine efficiency, satisfy emission requirements, and establish fuel pricing. For many applications, fuel specifications are outlined by professional groups (ASTM, ASME, GPA, CGA, NPGA), OEMs, fuel suppliers, or government agencies (EPA, DoD). See below for specific details about different types of fuel gas analysis.

Visit our contact page or give us a call today to get started!

Commercially Supplied Natural Gas

Natural Gas Analysis

Natural Gas is a naturally occurring mixture of hydrocarbon and non-hydrocarbon gases found in porous geological formations (reservoirs) beneath the earth’s surface. The chemical composition and heating value (Btu content) of natural gas can vary widely depending upon the reservoir source, processing and conditioning steps, and final treatment performed by the supplier.

Commercially supplied natural gas typically has the following approximate composition: 93% methane, 3% ethane, 0.5% propane, and trace amounts of higher hydrocarbons (C4-C6) along with 0.5-2% nitrogen and carbon dioxide. Low levels of water vapor, hydrogen, carbon monoxide, helium, oxygen, and C6-C14 hydrocarbons are normally considered negligible constituents of most processed natural gas streams as they will not alter the heating value appreciably at such low levels. Odorants such as tert-butyl mercaptan are typically added to the final natural gas product stream for leak detection and safety purposes.

Processed natural gas can be blended with reformed gas on a seasonal basis to increase its Btu content. In addition to fuel usage, natural gas is also a common feedstock for hydrogen generation, ammonia production, and a source of light hydrocarbons for chemical synthesis.

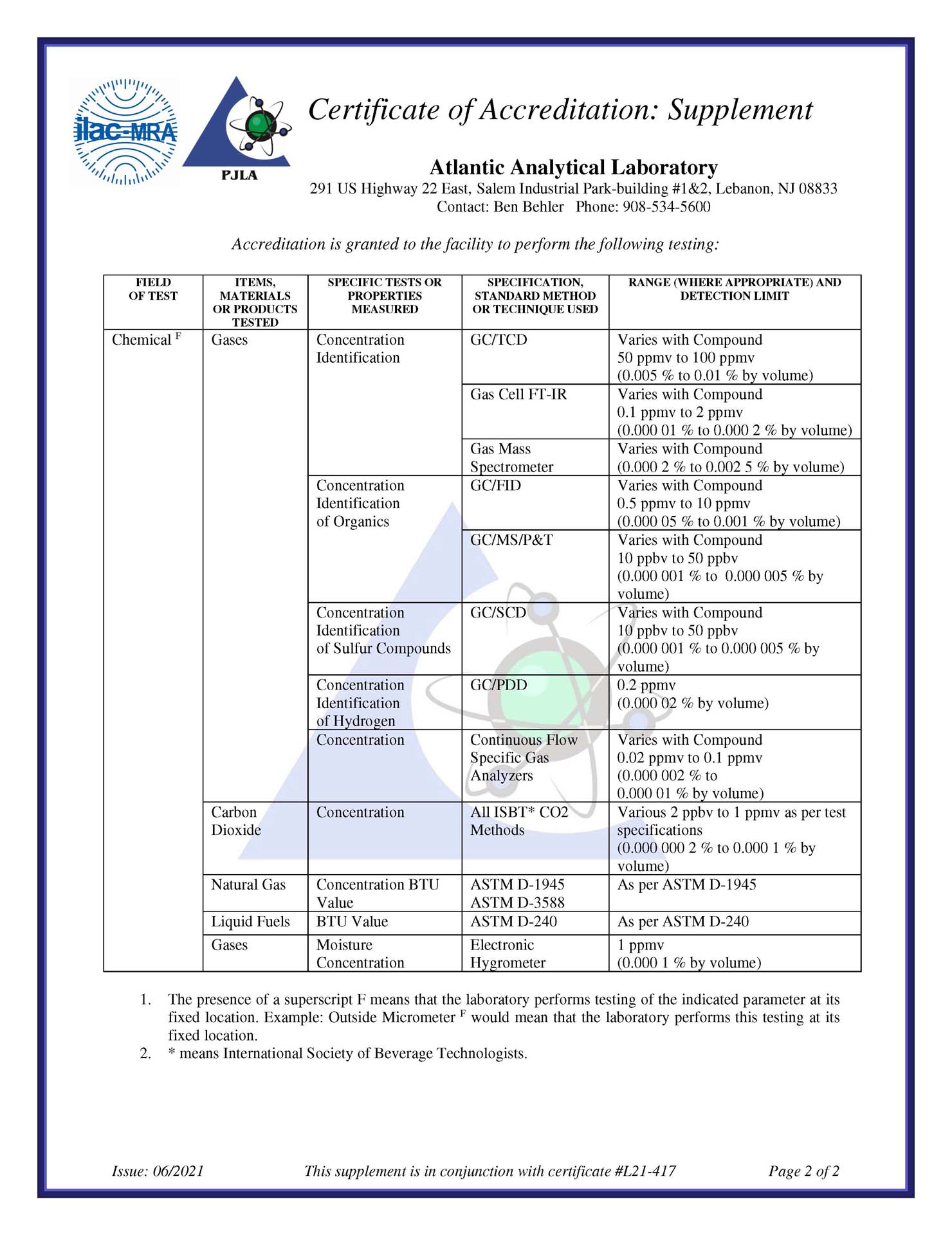

Atlantic Analytical Laboratory performs natural gas analysis daily, following published methods for both the main compositional analysis (ASTM D1945) and calculation of final heating and gas property values (ASTM D3588). Most natural gas samples are also analyzed for total sulfur content (ASTM D5504) due to state and federal environmental requirements limiting sulfur emissions.

Manufactured (Synthetic)

Gas Analysis

Many classes of gaseous fuels are commercially produced from solid or liquid hydrocarbons. Two common examples are:

- Refinery/HYCO Gas: Gases generated as by-products during the refining of crude petroleum. The composition of these gases varies with the petroleum source and can include significant hydrogen and/or sulfur content (hydrogen sulfide), light alkanes and alkenes, low levels of nitrogen, carbon dioxide, carbon monoxide, and trace oxygen.

- Reformed (Catalytic) Gas: A “tailored” gaseous fuel of high Btu content produced by fluidized or catalytic bed treatment of hydrocarbon gases at a refinery. The composition of reformed gas varies, but usually consists of hydrogen (11 – 22%), nitrogen (7 – 11%), methane (30 – 40%), ethane (13 – 16%), ethylene (13 – 16%), propane (0.5 – 2%), propylene (2.5 – 12%), and lower amounts of other light C4 – C6 alkanes/alkenes/dienes, carbon dioxide, and carbon monoxide. Such gases can be mixed with processed natural gas to increase Btu content.

Atlantic Analytical Laboratory can analyze synthetic fuel gases for composition, trace impurities, and presence of sulfurs or odorants. Contact AAL directly if you need a price quotation or are ready to submit samples.

Hydrocarbon Fuels

Liquefied Gas (LG) Analysis

Some hydrocarbon fuels exist as liquids when stored under pressure and are vaporized for use as fuels or for synthesis reactions. Common examples include:

- Ethylene/Propylene/Butylene/Butadiene: Normally high purity feedstocks (99.5+%) used for many fine synthesis reactions. Trace impurities such as hydrogen, carbon monoxide, carbon dioxide, oxygen, water, acetylene, light hydrocarbons, sulfur gases and oxygenates (alcohols, aldehydes, ketones, esters) are important impurities to be quantitated.

- Propane-Propylene grades: Commercial grade liquid propane (LP) is predominantly propane and/or propylene, which is commonly used for household cooking and heating applications. HD-5 Grade (special duty engine fuel) has a more tightly defined composition that is 90+% propane, 2 – 5% propylene and lower amounts of other C2-C5 alkane/alkene hydrocarbons. Ethyl mercaptan and tetrahydrothiophene are typical LP odorant additives.

- Butane-Propane (B-P) mixtures: Commercial grade liquid B-P mixtures are predominately used as fuels in climates and applications that do not experience low ambient temperatures.

- Butane-Butylene grades: Commercial grade liquid butane is predominantly butane and/or butylene mixtures that are used as fuels in industrial applications or as residential fuels in warm climate regions.

Atlantic Analytical Laboratory can analyze any of these liquefied fuel gases for composition, trace impurities, and presence of sulfurs or odorants. Contact AAL directly if you need a price quotation or are ready to submit samples.

Biogas (Digestor Gas)

Landfill Gas Analysis

As environmental conservation issues continue to grow in the public eye, focus has turned to renewable fuels such as biogas and landfill gas. These fuel gas sources involve processes that generate low Btu value gas mixtures from biological decomposition sources. While these gases do not provide as much potential combustion energy as natural gas and syngas sources, they can still be used for heat and energy generation instead of simply being uncaptured or vented to exhaust.

Biogas (digester gas) is a gaseous fuel mixture created by breaking down organic matter in either an oxygen-free environment (anaerobic digestion) or through fermentation. Biogas can be generated from agricultural waste, municipal waste, food waste, manure, sewage, and other biodegradable raw materials. Biogases are primarily composed of methane (50-75%), carbon dioxide (25-50%), and nitrogen (0-10%); common impurities of interest typically include sulfur compounds, siloxanes, and moisture.

Landfill gas is a gaseous fuel mixture created by biological decomposition of municipal waste by microorganisms. Similar to biogas, landfill gas is primarily composed of methane (40-60%) and carbon dioxide (40-60%); common impurities of interest typically include sulfur compounds, aromatic hydrocarbons, and volatile organic compounds (VOCs).

Atlantic Analytical Laboratory can easily analyze these renewable fuel gases for composition, heating value, and trace impurities of concern. Contact AAL directly if you need a price quotation or are ready to submit samples.

Alternative Fuels

Fuel Cell Hydrogen Analysis

Hydrogen is now being considered as an alternative fuel because it is renewable, abundant, efficient, and unlike other alternatives, produces zero emissions. Many believe that this versatile gas will become the primary fuel and energy carrier of the future. Hydrogen can produce electricity and electricity can produce hydrogen, creating an energy loop that is renewable and harmless to the environment.

Hydrogen combines chemically with most elements, so it has been utilized as an industrial chemical in a wide range of applications for many years. In vehicles, hydrogen can be used as a fuel in two ways: either to produce electricity in a fuel cell (the cleanest option); or in an internal combustion engine where emissions are significantly reduced compared with other fossil fuels. The reforming of natural gas by applying heat is currently the most economical process for producing hydrogen.

Atlantic Analytical Laboratory is currently working with major auto manufacturers, gas suppliers, and an ASTM committee that is creating new analytical procedures for fuel cell hydrogen applications. Because of the delicate nature of fuel cell chemistry, even trace amounts of impurities can greatly degrade vehicle performance and fuel cell lifetime. The analytical program we recommend is based on the specifications outlined in SAE J2719 (Society of Automotive Engineers).

Taking Great Care Towards

Sample Submissions

The most critical step in any analytical program is initial sample collection – great care must be taken to ensure the sample collected is truly representative of the source. AAL has a large selection of sampling cylinders and other sampling equipment available for all types of gas and liquefied gas sampling. If you are uncomfortable collecting samples or just want to make sure everything goes smoothly, we can send one of our experienced personnel directly to your facility to collect samples on site for you. We look forward to working with you soon!

gas analysis FAQs

A gas analysis lab tests and analyzes the composition of gases to ensure they meet safety, purity, and industry-specific standards. This includes checking for contaminants, verifying concentration levels, and helping companies maintain regulatory compliance.

Gas testing services are used by a wide range of industries, including food and beverage companies, pharmaceutical manufacturers, industrial suppliers, medical gas producers, and environmental agencies. Any business that uses or supplies gases can benefit from accurate and reliable gas analysis.

Atlantic Analytical Laboratory can test a wide variety of gases including oxygen, nitrogen, carbon dioxide, argon, helium, hydrogen, and many custom or specialty mixtures. We also test compressed breathing air, fuel gases, and gases used in medical and pharmaceutical applications.